- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

The automatic pillow packing machine is mainly used for packaging face mask,bread, chocolate, sweets, biscuit, vitelline pie, lollipop, moon cake, ice cream, card, wet tissue, spoon, toothbrush, soap, scourer ball, syringe, hardware, commodity and the products with regular shape.

| Availability: | |

|---|---|

| Quantity: | |

AMAN

Video

Product Description

| Model | Sl150 | SZ180 | SZ580 | SW80E | SZ502 | SZ602 | |

| Bagging size range | L(mm) | 130-400 | 60-300 | 60-350 | 90-450 | 120-550 | 120-500 |

| W(mm) | 30-140 | 35-160 | 35-160 | 35-200 | Max.220 | Max.220 | |

| H(mm) | 35-70 | 5-50 | 5-50 | 5-80 | Max.80 | Max.80 | |

| Packing speed(bags/min) | 30-110 | 30-180 | 30-350 | 30-100 | 30-120 | 25-120 | |

| Packing film width(mm) | 80-400 | 90-400 | 90-400 | 90-500 | Max.500 | Max.600 | |

| Machine weight(kg) | 670 | 400 | 600 | 700 | 1200 | 1500 | |

1.Compact machine structure with smaller footprint area.

2.Carbon steel or stainless steel machine frame with nice appearance.

3.Optimized component design realizing fast and stable packing speed.

4.Servo control system with higher accuracy and flexibility mechanical motion.

5.Different optional configurations and functions meeting different specific requirements.

6.High accuracy of color mark tracking function.

7.Easy to use HMI with memory function.

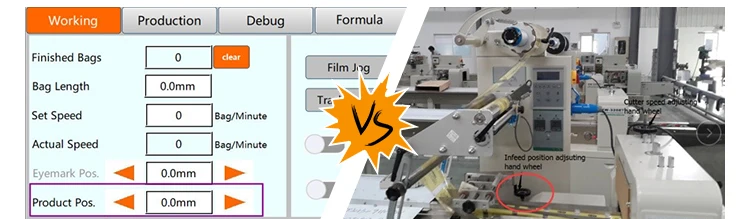

HMI7" :

HMI with memory function, easy to operate

Screen:Most of the daily operations can be performed through the touch screen. The operation interface is simpler and easier to use than the general model, and has a recipe memory function.

Servo control:3 Servo drive system, compared with the general frequency conversion control model, reduces the adjustment of mechanical transmission parts, and improves the accuracy of the motion.

Eye mark position value is adjusted via touch screen. Position value is directly showed on the screen.

In-feed position is adjusted via touch screen. No need to manually adjust the handwheel.

Our factories have advanced and modernized workshop, lead time for small flow packaging machines is greatly reduced from 30 days to 7-15 days compare others factory.